Printing Services

Who is FormFutura

FormFutura, founded in 2012 in Amsterdam, has grown from a local supplier of PLA and ABS into a global leader in additive manufacturing materials. With a complete range of filaments, resins, and adhesives, we serve over 400 resellers and customers in more than 75 countries. Our custom solutions, private label options, and strong reseller network ensure flexibility and accessibility worldwide. We prioritize sustainability through recycled products and eco-friendly packaging, and our experienced support team helps customers and partners succeed. By sharing knowledge openly, we aim to accelerate global adoption of 3D printing and shape a better, more innovative future.

Who is FormFutura

FormFutura, founded in 2012 in Amsterdam, has grown from a local supplier of PLA and ABS into a global leader in additive manufacturing materials. With a complete range of filaments, resins, and adhesives, we serve over 400 resellers and customers in more than 75 countries. Our custom solutions, private label options, and strong reseller network ensure flexibility and accessibility worldwide. We prioritize sustainability through recycled products and eco-friendly packaging, and our experienced support team helps customers and partners succeed. By sharing knowledge openly, we aim to accelerate global adoption of 3D printing and shape a better, more innovative future.

How does it work

Share Your Idea or Model

Got a 3D file or just an idea? We can help shape it into a printable design.

Get Expert Advice & a Quote

Together, we determine the best materials and settings. You’ll receive a clear, custom quote.

Printed & Shipped To You

We produce your parts in-house and send them out from our high-capacity distribution center.

What Makes Us Unique

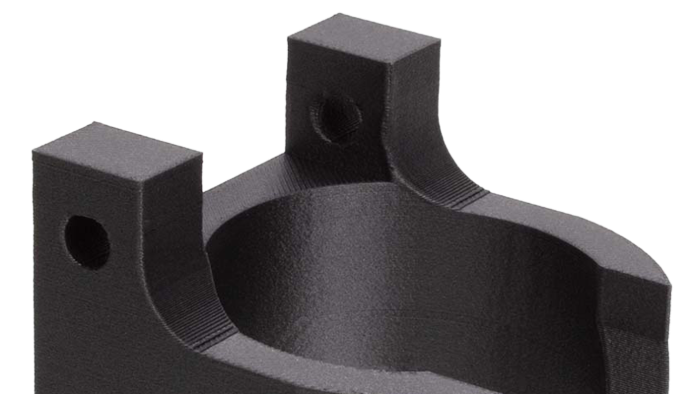

FormFutura is a specialist supplier of filaments, resins, and adhesives. By offering a complete range of 3D printing materials directly from our own inventory, we give our print service a unique advantage.

Our in-house stock includes everything from accessible materials like PLA and ASA to engineering-grade options such as Nylon, PEI, and PEKK. Making it easy to match the right material to your project's needs.

There are no sourcing delays and no material shortages. Whether you need a single prototype or a larger production batch, we can respond quickly and deliver reliably because everything is already on hand.

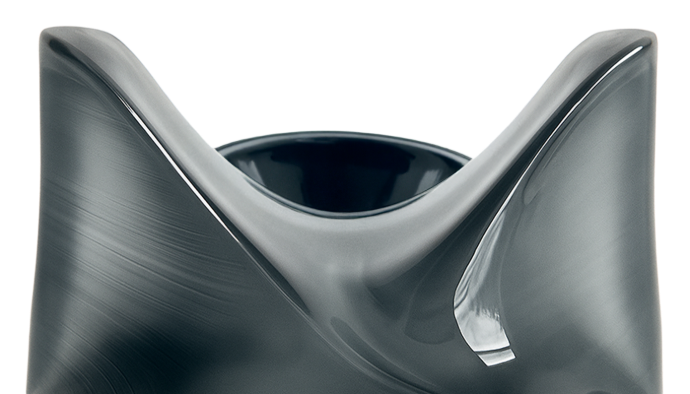

CAD Design and

Optimalisation Service

No printable design yet? No problem! We can assist with the entire process, from your initial idea and concept to a fully realized, high-quality 3D-printed product.

Our in-house Industrial Design Engineers bring over 12 years of experience in 3D printing and CAD modeling. We specialize in designing for additive manufacturing, ensuring that your model is optimized for printability, strength, and performance.

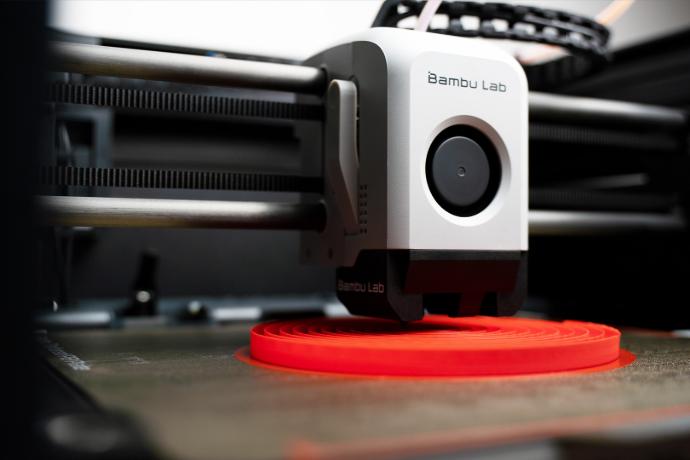

1000+

Materials with Colors

100.000+

Parts printed

250+

3D Printers

What Our Clients Are Saying

One-stop 3D printing service to develop & manufacture your products

We would like to help you move your project from start to finish. Our comprehensive services include development, design, and auditing to ensure your project meets 3D printing requirements.

Once ready, we can manufacture your products—all within a single facility.

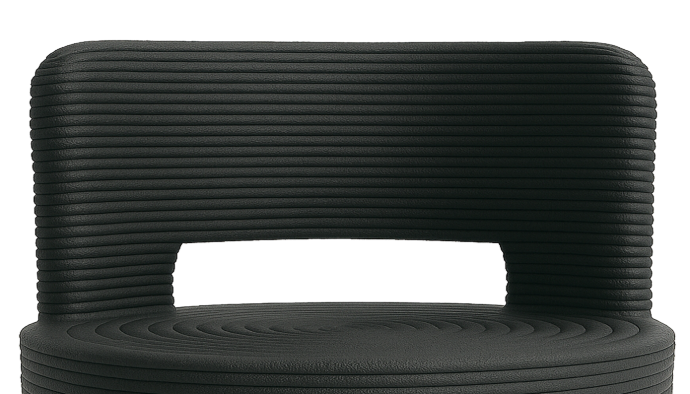

DFAM service - Design for additive manufacturing

Adopt your existing design to additive manufacturing

Powerful In-house 3D printing capabilities, with thousands parts per month

Creating & post processing/contactus

Frequently Asked Questions

The best 3D printing method depends on your project's requirements like material, strength, detail, and budget. Share your specifications, and we’ll recommend the most suitable technology.

Yes, we offer 3D printing services for both one-off prototypes and large-scale production runs, tailored to your needs.

Yes, our team can help optimize your design and guide you in selecting the best materials based on your project's requirements.

Yes, multi-color printing is possible depending on the chosen printing method and design. Let us know your needs, and we’ll offer the best solution.

We offer a wide range of materials including standard, engineering-grade, flexible, and recycled options in both filaments and resins to suit various applications.

Finishing options vary per production method, so it's best to contact us to discuss what’s possible for your project.